Navigating to Zero - June 2024

06/28/24

|

AWO's Moveable Bridge Quality Action Team Needs Your Input

The Moveable Bridge Quality Action Team--a cooperative initiative of the Coast Guard-AWO Safety Partnership's Mid-America Regional Quality Steering Committee--is working to prevent bridge allisions and other incidents by investigating and documenting issues encountered by our mariners when calling or transiting moveable bridges.

Beginning July 1, AWO and partners, including the Gulf Intercoastal Canal Association (GICA), will collect information about bridge-related problems such as:

AWO supports the Coast Guard's mission to enforce regulations that ensure safe navigation. Vessel operators, bridge tenders, bridge owners, and all other stakeholders in bridge operations must be held accountable for actions that impede safe navigation or contribute to an incident. To ensure robust enforcement, AWO, and our partners will inform the Coast Guard of each report of bridge-related problems that we receive in a formal letter to cognizant Coast Guard personnel. In addition, AWO will produce a summary report and trending analysis every six months.

We need your reports. Without member participation, we cannot achieve our mission. AWO has produced a form that will be shared with all members that outlines the necessary data. Members can use the form, which will be available on the AWO Resources Page shortly, or send information by email to Bridges@americanwaterways.com. Please ensure your reports include the following information:

To learn more about this effort, please contact Liam Morcroft at lmorcroft@americanwaterways.com.

American Waterways HERO Award -- Nominate Your Crew to Recognize Heroic Acts

Our industry's mariners work tirelessly to ensure the smooth flow of commerce while safeguarding our nation's waterways. While our industry is the safest mode of freight transportation, emergencies can and do still happen. In those crucial moments, our vessel crew members exemplify our industry-wide commitment to safety, leading first response and rescue efforts for their colleagues and their communities - actions that can aptly be described as heroic.

The American Waterways Honor & Excellence in Rescue Operations (HERO) Award recognizes these efforts, highlighting the heroism of our mariners and telling the story of AWO member company employees whose actions demonstrate selflessness, skill, and bravery. We need your help in identifying these heroic acts! Please acknowledge your employees' rescue efforts by submitting a nomination at americanwaterways.com/hero-award.

Qualifying events for the award include but are not limited to: rescuing commercial or recreational mariners, responding to a medical emergency onboard, recovering a person who has fallen overboard, responding to a person in distress while traveling to/from the boat, and other selfless service actions that reflect the safety culture of the American tugboat, towboat, and barge industry.

Awardees will receive a certificate of recognition for each vessel involved in the rescue, and each mariner will be issued a commemorative American Waterways HERO Award coin. Thanks to award sponsor 360 Coverage Pros & Berkley Offshore, mariners will also receive a one-year complimentary marine license and professional liability insurance policy.

Congratulations to this month's recipients of the American Waterways HERO Award:

To submit a nomination for the HERO Award or to learn more about the program, visit the HERO Award page on the AWO website.

To view AWO's new video, The American Waterways HERO Award: Honoring Industry's Heroic Mariners, click here.

Safety Professional Spotlight

Brian Bailey (bbailey@tradepointatlantic.com) is Director of Safety at Tradepoint Atlantic, located at the historic Bethlehem Steel Mill site in Sparrows Point, Maryland, right outside the Port of Baltimore. He manages all occupational safety and health initiatives, strengthening safety culture across Tradepoint Atlantic and its affiliates, including Tradepoint Rail, Maryland Materials Management, and Tradepoint Terminals, and ensuring compliance with safety standards. Previously, he was the Director of Safety & Environmental Stewardship at The American Waterways Operators, where his leadership in promoting industry safety earned him a 2020 Rising Star of Safety award from the National Safety Council. Brian's career has also included roles in trade association management, legislative advocacy, finance, and strategic planning. He serves on the Signal Mutual Indemnity Association's Safety Committee and the National Safety Council's Young Professionals Division, is a 2023 Leadership Baltimore County graduate, and sits on the Alumni Association Board of Directors for the University of Maryland, Baltimore County. He lives in a converted 200-year-old schoolhouse in Old Ellicott City with his partner and lab mix puppy.

Can you talk about Tradepoint Atlantic's culture and share an example of how it contributes to your safe operations?

Tradepoint Atlantic's culture is deeply rooted in creativity and innovation, crucial for its diverse yet complementary business operations such as commercial development, materials handling, marine terminal operations, and railroading. These elements have provided Tradepoint Atlantic with a competitive edge, attracting customers and fostering loyalty while enabling adaptation to evolving trends.

A prime example of this culture contributing to safe operations is Tradepoint Atlantic's prioritization of the safety and well-being of its workforce. Despite the complexity of daily activities at its 3,300-acre global logistics center, safety remains paramount. Whether employees are stevedores, heavy equipment operators, mechanics, maintenance technicians, railroaders, or in any other role, the company is committed to ensuring that every employee returns home safely at the end of their shift.

This dedication extends beyond compliance with regulatory standards - it is reflected in Tradepoint Atlantic's culture of continuous improvement in safety. By valuing and empowering employees to contribute ideas, the company enhances overall satisfaction and nurtures a sense of ownership in achieving collective success while maintaining operational excellence.

Can you speak to a milestone or goal you've achieved recently in your safety program and discuss any new or continuing initiatives that Tradepoint Atlantic is considering in 2024?

June marks National Safety Month at Tradepoint Atlantic, when we especially celebrate our employees' safety achievements. During my first Safety Month here, we created a marketing video featuring employees discussing how they promote safe behavior at work. Last year, we initiated the #WhyIWorkSafe campaign, encouraging our team to share their personal motivations for adhering to safety protocols, whether for their families, livelihoods, or colleagues.

This year, we're focusing on the National Safety Council's themes: safety engagement, roadway safety, risk reduction, and preventing slips, trips, and falls. We've distributed digital quick tips, toolbox talks, safety tip sheets, and games and puzzles to engage employees. The site has been lively with fun activities and treats, including food and snowball trucks.

Since late 2023, Tradepoint Terminals has expanded to handle a wider variety of cargo shipments, necessitating some new and revised standard operating procedures to ensure safe unloading, handling, warehousing, and outbound shipping. As we progress through 2024, we are developing initiatives to further enhance safety, particularly focusing on our newer employees. It's crucial that they understand their job responsibilities, especially regarding safety, as they are at a higher risk of incidents. Our safety program, which focuses on training, hazard elimination, and enforcing safe work procedures, is vital for preventing injuries and ensuring that all employees, especially those newer and less experienced, actively contribute to a safer workplace environment.

You have been highly successful in your maritime career! For those who are unfamiliar, can you share how you came to work in maritime safety and any advice for someone considering the maritime transportation industry for their career?

My journey into maritime safety began with my love for water, rooted in my childhood in the Chesapeake Bay region. Surrounded by water activities like beach outings and crabbing, I developed an appreciation for the water.

Initially, my interest in safety was sparked by a desire to contribute meaningfully at work. Over the past eight years, this has evolved into a commitment to ensure that a company's most valuable asset--its people--are safe, well-trained, and prepared to handle incidents. Safety is about creating a culture of shared responsibility where everyone is empowered.

Navigating the complex landscape of safety, I've learned that ensuring compliance with regulations is about more than just enforcement - it's also about coaching and leading. I guide employees, helping them see that safety practices are both manageable and essential, and support them in adopting a proactive approach to safety.

I chose a career in safety to make a difference and to be a voice for those who didn't have one, moving beyond blaming "human error" to ensure better treatment and thorough investigations. Safety is more than just a workplace requirement - it's a lifestyle that extends to all aspects of life, including home, the gym, and family activities.

For those interested in the maritime transportation industry, my advice is to be passionate and committed. Safety demands dedication, resilience, and a genuine desire to improve. Embrace the challenges, stay focused, and remember that your efforts help create a safer environment for everyone.

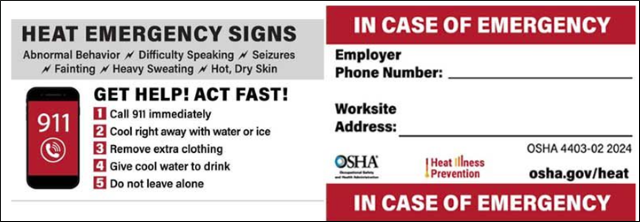

OSHA's Heat Injury and Illness Prevention Proposed Rule is One Step Closer to Publication

The U.S. Occupational Safety and Health Administration (OSHA) is proposing a new standard to protect workers from excessive heat which is with the White House Office of Management and Budget for final review and is expected to be released before the end of 2024. The proposed rule will apply to workers subject to OSHA's authority, which includes shipyard workers, shoreside-based maintenance personnel, and many other industrial workers; however, the rule will not apply to mariners working aboard inspected vessels due to OSHA's MOU with the Coast Guard, which defines the limits of OSHA's authority over the occupational safety and health of seamen.

While awaiting the new rule, OSHA can cite employers for heat-related violations under the General Duty Clause, which requires a four-part test to prove violations. OSHA has emphasized the importance of all employers implementing a heat safety plan that includes consideration for acclimatization, water, rest, and shade for workers, especially for those new or returning to high-heat workplaces. For more tools and information related to heat injury prevention, visit:

OSHA's Heat Injury and Illness Prevention webpage: https://www.osha.gov/heat/

The Centers for Disease Control's Heat & Health Tracker: https://ephtracking.cdc.gov/Applications/heatTracker/

AWO High Potential Learning Value Near Miss

Near Miss and Stop Work events are leading indicators that allow vessel operators to identify and address weaknesses in a safety management system before a hazardous condition or lack of procedure contributes to an injury or incident.

We highlight recent High Potential Learning Value Near Misses submitted voluntarily by AWO members. Please submit your own Near Miss or Stop Work event using this form. To see all published High-Value Near Misses, please visit the AWO Resources website: https://www.americanwaterways.com/resources.

MEMBER-SUBMITTED NEAR MISS 24-05T: Lowering H2S Concentration Before Transfer of VGO

NTSB Investigation Report: Contact of Queen City Tow with Vane Dike

On March 28, 2023, at 0224 local time, the towing vessel Queen City was downbound on the Ohio River in high-water conditions, pushing an 11-barge tow, when the tow struck the Vane Dike at the arrival point for the McAlpine Locks and Dam in Louisville, Kentucky, and broke apart. No pollution or injuries were reported. Total damage to the barges and cargo was estimated to be $1.98 million. To read the full report, visit the NTSB's website.

Investigation:

The Queen City had 11 barges in tow, including 4 empties, 6 loads of corn, and 1 load of methanol. Company policy requires at least 250 HP available per barge. Rated at 3,000 Hp, the Queen City was compliant with company policy and regulation at the time of the incident.

In March of 2023, the Ohio River was experiencing near record-high water levels. This high-water event required the activation of a Waterways Action Plan (WAP) for the area, which included guidance and warnings for mariners about:

The Queen City pilot and Captain had discussed the risk of dam outflows impacting the tow during their voyage planning. Their plan called for the pilot to steer into the current after passing the Clark Memorial Highway Bridge. Despite the plan, the pilot was unable to overcome the strong current and his tow was pushed out of line, leading to the allision and breakup of the barge tow.

Lessons Learned:

Mariners should ensure their voyage planning includes:

Did You Know?

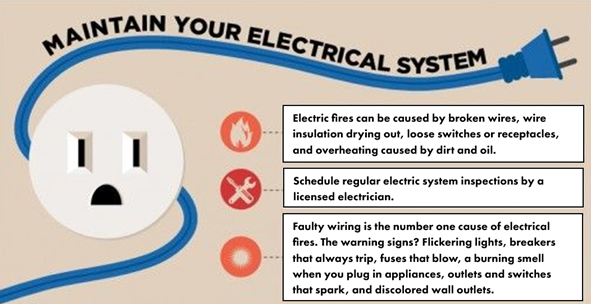

A wrinkled electric cord is a sign of an overloaded circuit. The 'wrinkles' result from the wires inside of the insulating sheath overheating. Damaged cords should be taken out of service immediately. Never use extension cords to power appliances that draw more amps than the cord is rated for, and never connect two extension cords. Remember also that extension cords are for temporary power ONLY.

OSHA Publishes Update to Hazard Communication Standard

OSHA has updated its Hazard Communication Standard (HCS) to align with Revision 7 of the United Nations' Globally Harmonized System of Classification and Labelling of Chemicals (GHS). The final rule takes effect on July 19, 2024. Here are the key changes:

Hazard Classification:

Labels:

Safety Data Sheets (SDSs):

The changes are designed to protect workers by providing clear information about the potential hazards of chemicals and updating safe handling, storage, and disposal rules. For more details, the full rule is available here. A summary of the updates included in this rule is available here.

Behavior-Based Safety: Explained

The term Behavior-Based Safety, or BBS, is "a concept that focuses on influencing employee behaviors as a route to safety improvement, emphasizing the idea that many maritime accidents are preventable through the modification or elimination of unsafe behaviors," according to Murray Goldberg of AWO member Ripple Operations.

In "Training Tips for Ships," Mr. Goldberg, CEO of Marine Learning Systems, which recently merged with Ripple Operations, reviews BBS in depth. Mr. Goldberg built one of the first commercially available Learning Management Systems and has been writing training blogs for Marine Link and Maritime Reporter since 2019. To read more about BBS, follow this link to the full article.

Coast Guard Releases 2023 Recreational Boating Statistics

The U.S. Coast Guard recently released the 2023 calendar year statistics on recreational boating accidents, reporting a decrease in fatalities and accidents. A summary of data from the report is included below. Click here to read the full report.

Interregion and Coastal Safety Committees' Summer Meeting Set for Chicago, August 14-15

AWO's Interregion and Coastal Safety Committees' Summer Meeting is scheduled for August 14-15 in Chicago. The event will include a discussion of lessons learned from the Key Bridge allision response, a case study on a barge breakaway and stranding at the McAlpine Dam structure, an update on SIRE 2.0 by OCIMF, a discussion of shipyard challenges for the safety manager in coastal and inland waterways, and much more!

Contact Michael Breslin (mbreslin@americanwaterways.com) to learn about safety sessions or Caitlin Clark (cclark@americanwaterways.com) for registration questions and concerns. Register to secure your spot.

Safety Statistics Reporting Program -- 2nd Quarter Statistics Due

Your Second Quarter 2024 safety data are due before July 30. Please visit the Safety Statistics Reporting Program Website to review the process and enter your data for the second quarter and any historical data that may be missing. Your submission is confidential and crucial to our industry's benchmarking, advocacy, and safety and sustainability initiatives.

If you have any questions about the SSRP, please contact mbreslin@americanwaterways.com.

Moxie Releases Near Miss Reporting Training Video

AWO member Moxie Media recently announced the launch of its latest training program, Near Miss Reporting for a Safer Workplace. This comprehensive program aims to educate employees on the importance of reporting near misses to enhance workplace safety and prevent potential accidents. The program helps students differentiate between near misses, accidents, and hazards. Click here to learn more about the program.

SIRE Inspection Integration Announced for Helm CONNECT

AWO member company Helm Operations recently released a tool that simplifies SIRE inspection recording. Trevor Atkinson of Helm CONNECT shared how users can now automatically import SIRE inspection reports to their system, eliminating manual data entry and saving valuable time and key resources.

Trevor noted that Helm also provides an "Audits Dashboard" that displays clear and actionable visualizations based on inspection findings to help users make informed decisions and further optimize crew and vessel performance. To learn more about this integration, visit helmoperations.com.

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||